Technical Facts

Of course materials should not only look beautiful and feel good, the technical facts have to be correct, so that set standards at installation for example for industrial buildings or cruise liners are complied with. Products made of Resysta have been audited, tested and certificated many times.

Thermal Expansion

Resysta is a thermoplastic and is affected by thermal expansion like many other materials. At installation it is absolutely necessary to keep the distances indicated in the installation guides.

Thermal coefficient of linear expansion (ASTM D696): 3,6 x 10-5 m/mC. This corresponds to a length expansion of 0,36 mm per meter at a temperature change of 10°C

Fire Protection

Products made of Resysta are assigned as standard to fire protection class B2 (normal flammability). Depending on the material type and profile class B1 (low flammability) can be achieved. Therefore profiles of Resysta are partially certificated according DIN EN 13501-1 with E which is of low flammability (B-S2, d0).

In shipbuilding, Simowood boards by Simona feature a very high flammability class - an IMO-certification was achieved. Therefore the material with this can be also be used for cruise liners. Appropriate compounds are produced by Ineos and Polymer-Chemie.

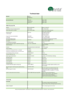

Certification Overview

Germany/Europe:

Norm: EN ISO 11925-2 B2

Result: normal flammability (with additional treatment B1 achievable)

US Norm NFPA:

Norm: ASTM E84 Class A

Result: flame spread 25, smoke emission 450

Great Britain:

Norm: BS 476 part 6&7

Result: Class 1